Welcome To

Transform your production process with intelligent automation

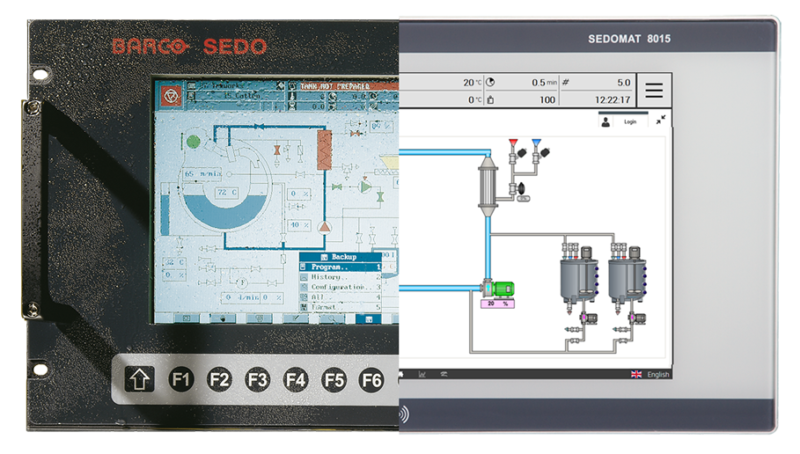

High quality controller designed for your smart factory

Additional cost-effective member of the sedomat 6000 family

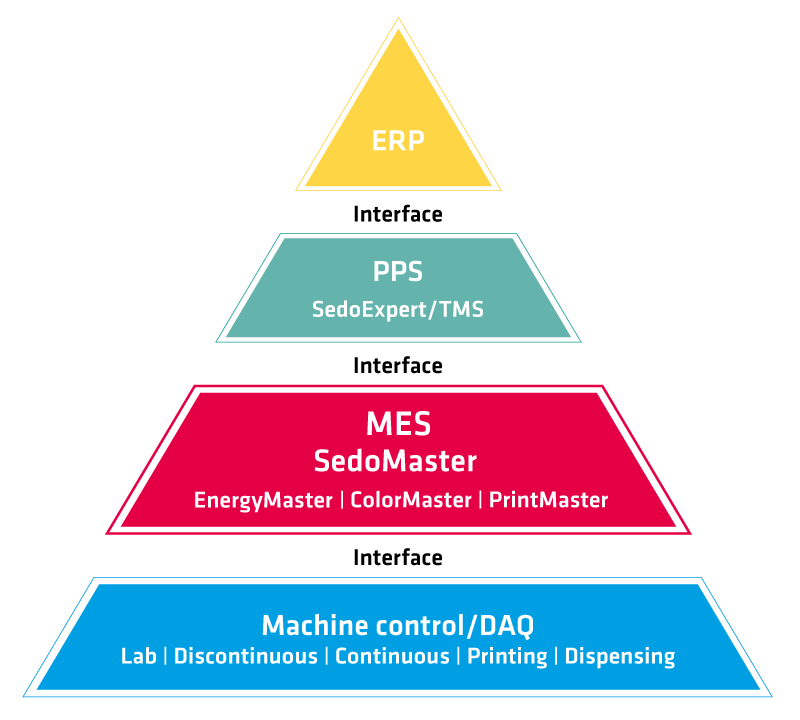

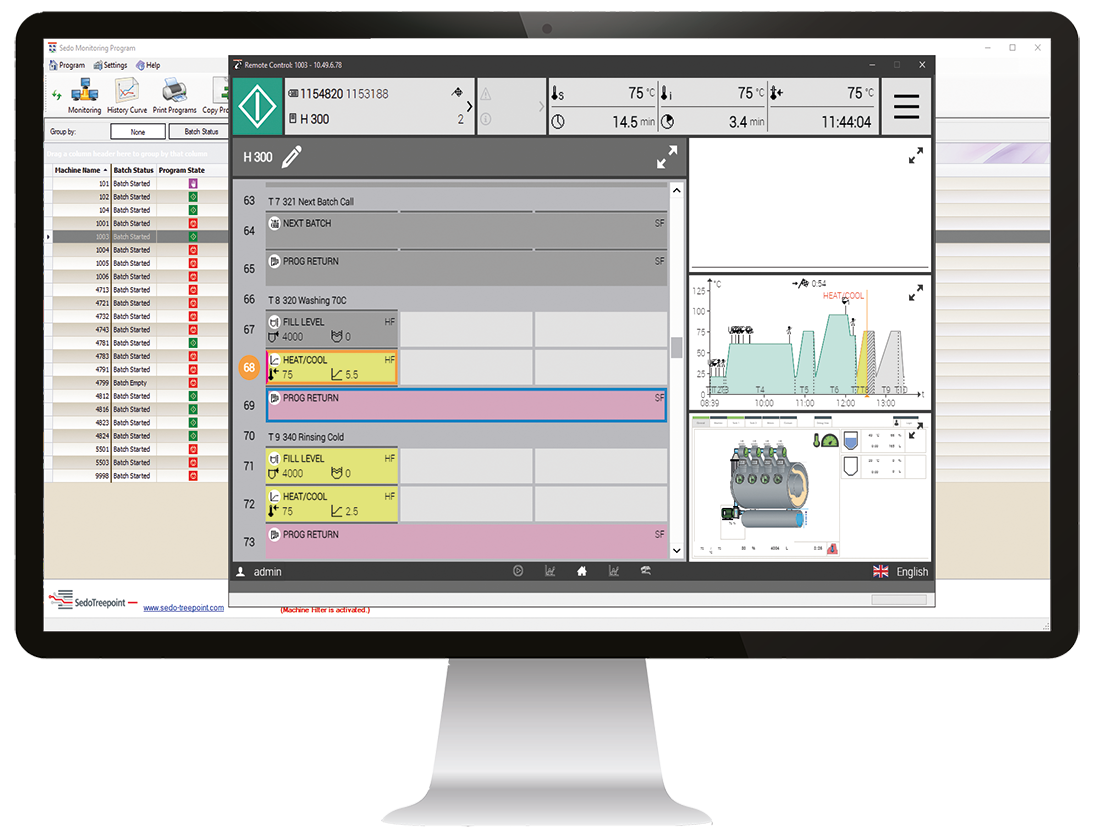

MES-Systems are needed as the foundation to bring the vision to life and realize the full benefits. With interfaces to machines and other required systems, the ERP system and the Production Planning System (PPS), Sedo Treepoint MES-Systems are a central tool for the entire workshop to get real-time insights for better production and business performance.

A strategic solution for the textile dyeing and finishing industry. The system supports all required interfaces to other systems such as Chemical dispensing, Recipe management and ERP. This results in an increased efficiency of the processes as well as in the optimization of all machinery and this in cost minimization.

>> Supports new Sedomat 6000/8000 Series as well as other Sedomat controllers

>> Provides IIoT-enabled production for the Smart Factory

>> Production control leads to increased productivity and quality improvement

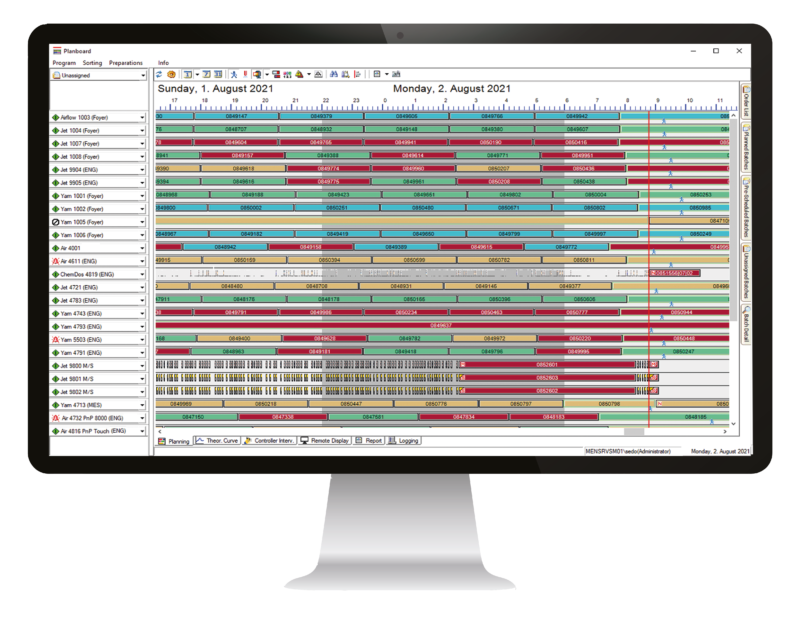

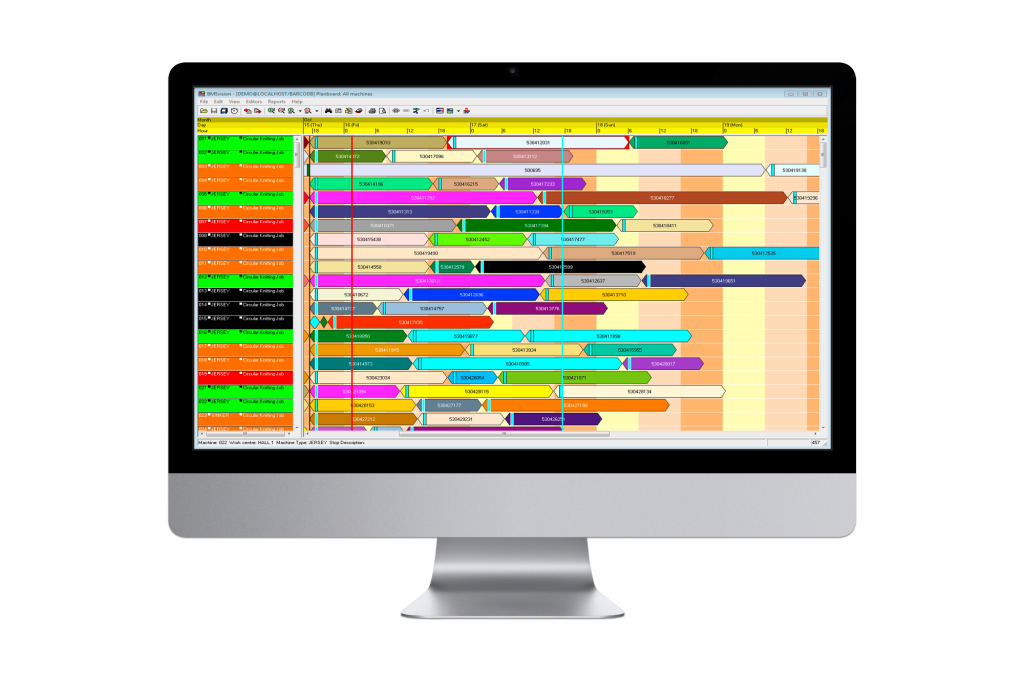

>> Real time interactive planboard, powerful reporting and dashboard

>> Single, integrated view of production data for improved decision-making

>> Less CO2 emissions trough optimized processes

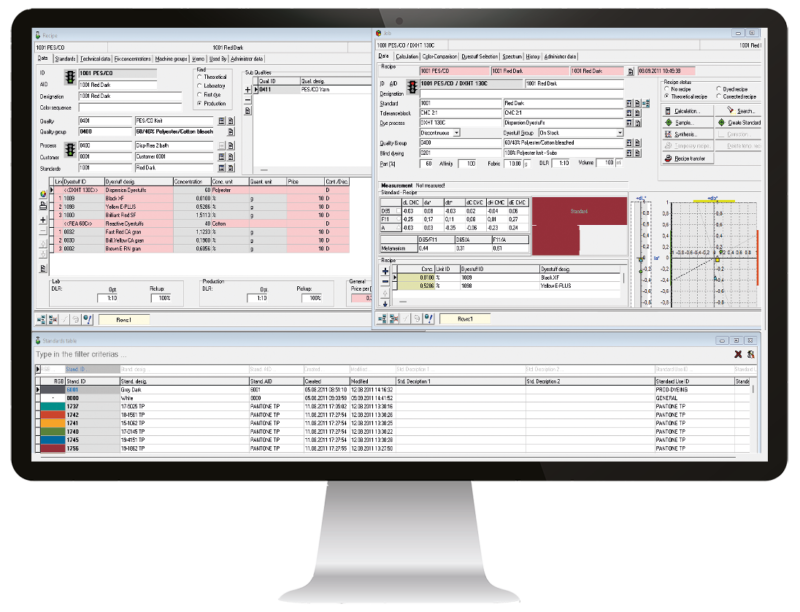

>> Expert system for recipe management and color measurement

>> The Windows-based software package ColorMaster is an expert system for recipe management and color measurement. In the laboratory the system allows the best and most cost-effective recipe to be calculated. For production, the integrated processes within ColorMaster offer the best possible treatment and define the correct dye program. Colorimetric control for the different production steps and calculations of additions with addition treatments enhance the functionality of the system. To create a dye house with completely optimized automatic production, ColorMaster is, together with the management system SedoMaster, a powerful and necessary tool.

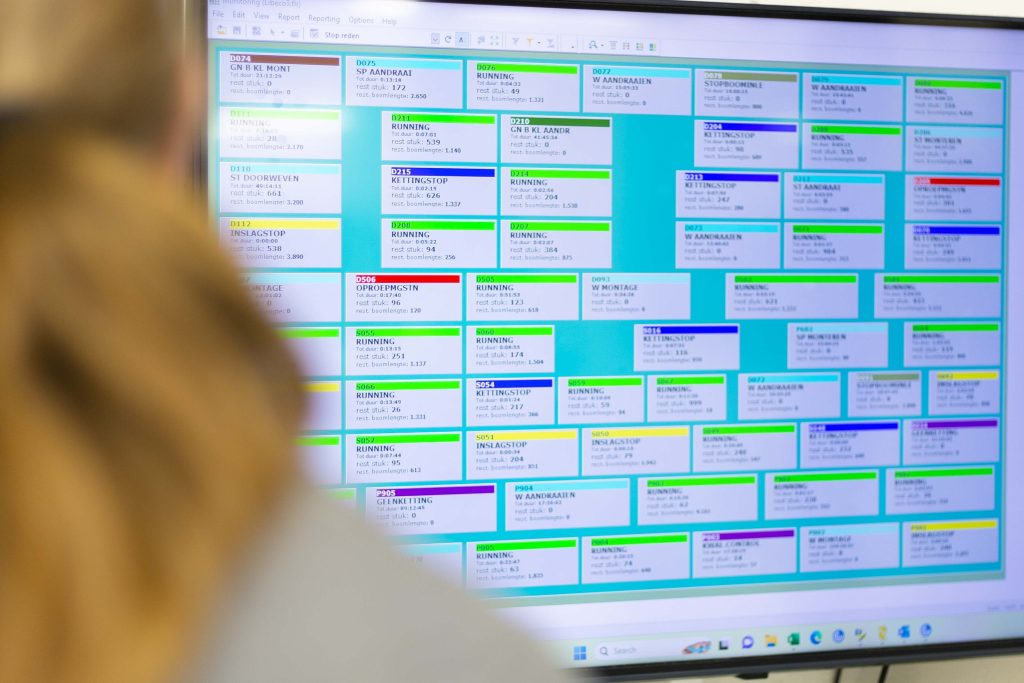

KnitMaster is the world's leading MES system for the knitting industry

>> Real time data collection

>> Production monitoring

>> Management reporting

>> Production scheduling

>> Interface with ERP system

>> Yarn inventory management

>> LFA (yarnd feed consumption) monitoring

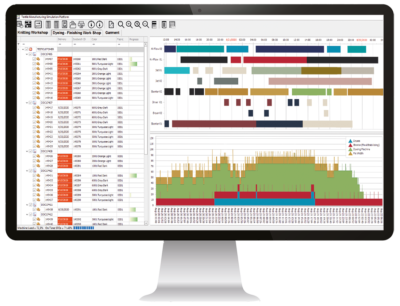

WeaveMaster is the world's leading MES system for the weaving industry.

>> Real time data collection

>> Production monitoring

>> Management reporting

>> Production scheduling

>> Ticket printing

>> Interface with ERP system

>> Traceability

>> Event and alerts

Production and quality monitoring for the complete spinning mill

>> Real time data collection

>> Production monitoring

>> Quality monitoring

>> Production scheduling

>> Interface with ERP system

>> Preventive maintenance

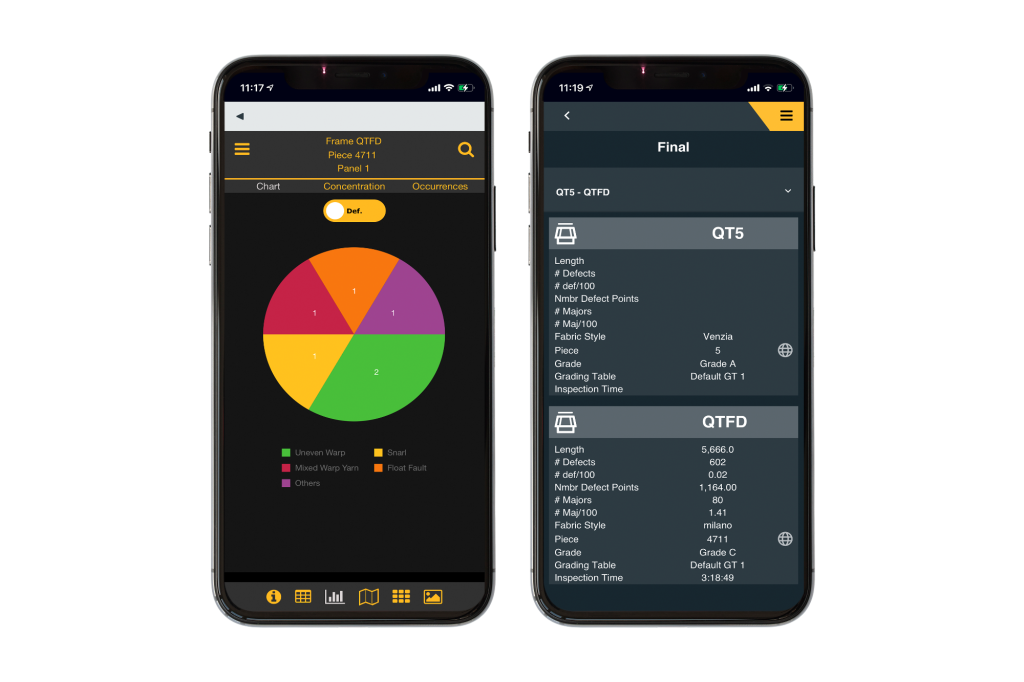

Fabric inspection and optimized cutting

>> Reduced off-quality through on loom inspection

>> Real time alarms in case of quality problems

>> Customer specific ticket printing

>> Full quality reporting

>> Monitoring inspector efficiency

>> Extreme flexibility through built in report generator

>> 24/7 informed about the quality in the mill

>> Real time Energy monitoring

>> Increased efficiency and quality level

>> Connects with other systems

>> Reduce energy costs

>> Improve sustainability

>> Reduce carbon footprint – save costs

Expert software for the fully automated textile industry

“Smart Leuco-Indigo” is produced in an electrochemical process consuming considerably fewer resources than existing methods. Using only indigo pigment, caustic soda, water and electricity. In a fully automated process, the clean Leuco-Indigo is produced, metered and fed directly to the dye bath. The Smart-Indigo™ solution is the most sustainable way to dye denim.

Message from the Management

Thank you for showing your interest in OUR products !

As the exclusive agents of SEDO TREEPOINTS, BMSVISION, SMART INDIGO brand Products in Bangladesh, we have always maintained long-lasting professional relationships with our customers. As a result, we can proudly claim that all the leading textile industries in Bangladesh are our clients. In fact, the success stories are a testament to both the unquestionable quality of our products and the high level of trust that our clients have placed on us.

S M Engineering is also exemplary in providing value-added services to customer; we are committed to meet our customers’ needs with utmost efficacy and sincerity. We not only aim to use our human resources and capital to serve the various needs of our esteemed patrons in the minimum amount of time but also distinguish relevant and beneficial growth opportunities for them. Be it in providing our stakeholders with the right solution for their projects, or by offering pre-and post-sales services and/or product support, or by running system integration or system management and monitoring control, we are always ready to walk an extra mile for ensuring customer-satisfaction.

Our paramount concern is to build a long-term vendor relationship on which our valued customers can depend on. With the promise of excellence in service, we look forward to a long and satisfactory relationship with all our clients.

Yours truly,

Our Products

Our Service

Book your service with us!

Exhibitions

BTKG Expo 2026

April 29. – May 2. 2026 | Bangladesh International Textile Knitting and Garment Industry Exhibition 2026 DHAKA, BANGLADESH, International Convention City Bashundhara, Dhaka. Visit us in hall 8 – booth 400!

ITM 2026

June 9. – 13. 2026 | The largest exhibition in Turkey and in the region ITM among the most important exhibitions in the World Visit us in hall 12 – booth 1203A!

ITMA ASIA + CITME 2025

October 28. – 31. 2025 | The Springboard to Regional Markets in Southeast Asia, Middle and North Africa and Central Asia SINGAPORE Singapore Expo

DTG 2025

February 20. – 23. 2025 | The 19th Dhaka Textil & Garment Machinery Exhibition 2025 DHAKA, BANGLADESH International Convention City Bashundhara, Dhaka Visit us at hall 8 – booth 603!