Service

First class service for your investment

- Fast delivery of high-quality spare parts worldwide

- Continued support for many of our older systems

- Customized service agreements guarantee the best possible support for your manufacturing process at all times

- Remote diagnosis of your machines and control by our experienced engineers while production continues

- Automatic reminders for maintenance and service work

- Sometimes a repair is more useful than a new spare part. To avoid production downtimes during repair, we offer loaner equipment.

OUR service Division for the exemplary services provides to its patrons with a vision “Our services are of such high standards that Customers will buy our products to access our unparalleled services”. A number of skilled engineers and service personnel work relentlessly round the clock to provide support to the wide range of machineries- all across the country. Because we value “Customer Success and Satisfaction”, we provide unparalleled coast-to-coast product and service support through our 24/7 Service, our well-trained technical personnel.

Be it anywhere and anytime, we are always ready and happy to walk an extra mile for supporting our customers’ interests and for safeguarding their investments.

We also have topnotch technical expertise for specialized functions like: Commissioning, Preventive Maintenance, Trouble Shooting and Providing Machine.

All this and many more only to give you premier customer services.

We also deliver expedite and excellent field services to our esteemed patrons through a range of support undertakings. Since customer success and satisfaction is our paramount concern, we organize frequent sessions/ programs for training our customers regarding the operation and maintenance of their procured our supplied products.

Additionally, SM ENGINEERING are also available for supervising and for providing extra support facilities. Our service department also has a program to improve our customer service; in addition, we’ve also implemented SKILL Development program and Continuous Customer Satisfaction Survey to improve customer satisfaction in all facilities & branches and to enhance the quality of service respectively.

We are committed to offer you will all sort of services for heightening the efficacy of every aspect of your operation. Our Complete Solutions, Constructive Work Order processing by Enterprise Resource Planning (ERP) project

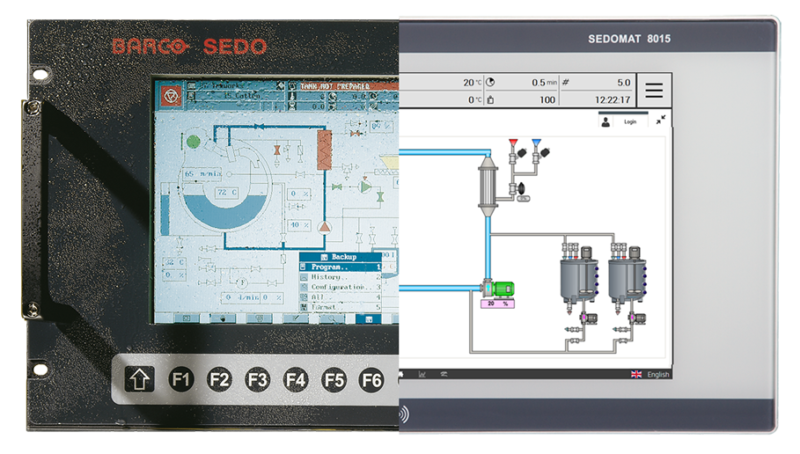

Machine Modernization

Small investment – latest technology

Upgrade your Sedomat 5000 to the latest technology – Sedomat 8015. The new controller series is designed to meet future standards through its high flexibility and contains all the benefits of the well proven Sedomat controllers. With the Sedomat 8015 your machine is ready for Industry 4.0.

Advantages

- Minimization of machine downtimes

- Increased efficiency

- Ensuring the availability of spare parts

- Savings in energy

- Updated interfaces, connection to latest systems

We determine the necessary scope and develop a concept suitable to your needs.

Please contact us, if you are interested in a retrofit of your machines.

Software Service

We are constantly working on the development and improvement of our software solutions and recommend continuous software updates to ensure smooth operation of the systems.

Please contact us for further information:

Consulting and Project Management

We provide the best possible service and support for the implementation of complex systems to your dyehouse or textile finishing plant.

Please contact us for further information:

Textile Dyeing Machine Automation Systems

We Globally Developed and Supply Integrated Automation Systems for Textile Dyeing Machines From Fiber to Garments

We Can Supply Automation System For Any Kind of Textile Machine Like Fiber Dyeing, Yarn Dyeing, Hankdyeing , Farbic Dyeing(Ujet, Longtube, Softflow, Overflow Etc),Garments Dyeing,Paddle Dyeing

We Can Supply Textile Dyeing Machine Automation System For Your New Or Existing Machine Also Upgrade Your Existing Machine

We Are System Intergator For

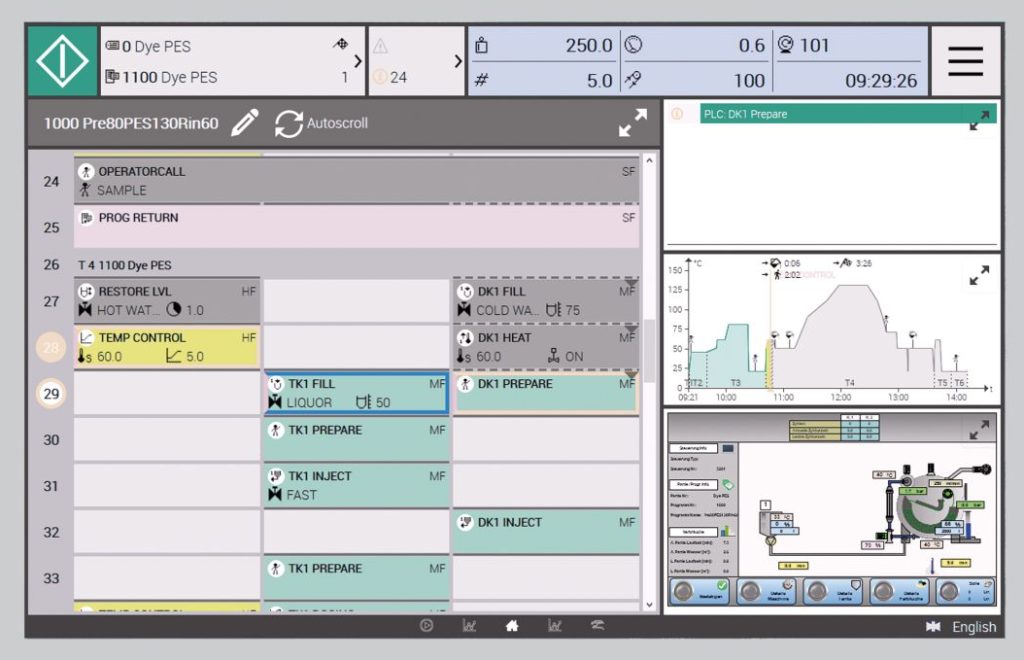

SEDO TREEPOINT – Experts in process optimization

has been developing and producing benchmark products for 30 years. Our systems, operating in all areas of textile finishing, have improved both quality and productivity. Furthermore the production data logged by our systems, plays a key role in helping management not only to make the right decisions but also to achieve appropriate company certifications.

Using our systems to enable the latest production methods can help our customers avoid wasting water and power thus reducing both bills and CO2 emissions.

Our product program comprises: ·

- Controllers, PLC’s, I/O ´modules and sensors for machine automation

- Software for central production planning and supervision

- Data acquisition

- Recipe and color management software for laboratory and production

- Quality control systems for laboratory and production