Sedomat 6000/8000 Series Details

Sedomat 6000 Series

The cost-effective solution for high degree automation

Designed for the Smart Factory

The Sedomat 6000 series has been specifically designed to meet and exceed the latest

Industry 4.0 requirements. As a cost-effective alternative to the top-level controllers,

the Sedomat 6000 series combines all premium features and has been developed with a focus

on future-proof flexibility. All the proven benefits of the Sedomat series have been integrated

into this generation of controllers and expanded to include internal WiFi, RFID, versatile fieldbus

capabilities and numerous modular internal and external inputs and outputs.

.

.

.

.

.

.

.

.

.

.

Powerful hardware, high quality standards

Solutions for dyeing and finishing automation need expert systems. The powerful hardware offers an impressive user experience and brings together the knowledge of more than 40 years of machine automation in dyeing and finishing. Like all Sedo Treepoint controllers the Sedomat 6000 series guarantees high quality and reliability in rugged production environments and is build according to the highest quality standards. By choosing between a user-friendly 7” or big 10” touch display, customers have different options for their operation needs and requirements.

Sedomat 8000 Series

The new standard in dyeing and finishing

Designed for the Smart Factory

The Sedomat 8000 Series is specially designed to meet the latest requirements of Industry 4.0 and more. It is developed to match future standards through its high flexibility. The controllers contain all the benefits of the well proven Sedomat controllers combined with internal WiFi, RFID, flexible field bus and a high number of modular internal and external in- and outputs. Energy counters can directly be connected via the high number of standardized connections. It already includes a PLC which can be adapted with programming tools and can be optionally equipped with internal and external I/O boards to meet the different requirements of yarn, fabric and other types of dyeing machines.

.

.

.

.

.

.

.

.

.

Top-level, high quality products

Solutions for dyeing and finishing automation need expert systems. The Sedomat 8000 Series brings together the knowledge of more than 40 years of machine automation in dyeing and finishing. It is tested for rough production environments and build according to the highest quality standards. The powerful hardware offers an impressive user experience.

Video Sedomat 6000 / 8000 Series

Sedomat+ Series Details

Touch screen controller for dye house and continuous machines

Important note

After being on the market for about 18 years and having proved to be longstanding high-quality products, we need to inform you that the production of the current Sedomat Plus series (Sedomat 1808+, Sedomat 2500+, Sedomat 2600+ and Sedomat 5500+, Sedomat 2800+/5800+) will gradually fade out.

Of course, we still offer spare parts, repair and service for existing devices.

Our Sedomat 8000 Series offers high class replacement with many cutting-edge features for Smart Factory automation.

Sedomat 1808+

Sedomat 1808+ offers a 7″ user-friendly touchscreen display and is waterproof to IP67.

It guarantees high quality and reliability for rugged environments. The RFID reader offers a possibility in data

acquisition.

The internal I/Os can be configured to meet the requirements of yarn, fabric and other types of dyeing

and finishing machines.

In addition to these features, the Sedomat 1808+ offers many other advantages

for your production.

Sedomat 2500+

Sedomat 2500+ offers a 6,4″ touchscreen display with user-friendly interface.

This compact controller combines touch screen interface with internet technology and is equipped with RFID reader which offers a possibility in data acquisition. Sedomat 2500+ is waterproof to IP 67 and guarantees quality and reliability in rugged production environments.

Adaption to all types of dyeing and finishing machines is possible through internal I/Os.

The Sedomat 2500+ offers even more advantages for your production.

Sedomat 2600+

Sedomat 2600+ comes with a 8,4″ touchscreen display with intuitive user interface, which can easily adopted by operators. Like all other controller of Sedomat+ Series it is waterproof to IP67 and therefore ideal for rough production environments. Also, it is equipped with RFID reader which offers possibilities in data acquisition.

The onboard modular I/Os of the Sedomat 2600+ can be configured to meet the requirements of different dyeing and finishing machines.

Additional to these points, the Sedomat 2600+ offers even more advantages for your production.

Sedomat 5500+

Sedomat 5500+ is equipped with the largest display of Sedomat+ Series. The 12,1″ touchscreen display also offers a user-friendly interface for easy operation. Being waterproof to IP67, it guarantees high quality and reliability for rugged production environments.

Having an RFID reader, it offers new possibilities in data acquisition. Internet web browser technology running on the Windows CE operating system means the Sedomat 5500+ can be controlled remotely from any PC on the factory network.

In addition to these features, the Sedomat 5500+ offers many other advantages for your production.

Continuous Controller

Touch screen controller for continuous machines

Sedomat 2800+

Sedomat 2800+ is suited for the automation of compact continiuous machines like calendars, singeing machines, winding machines and dryers.

Machines with up to 40 process parameters can be controlled. The controller is also waterproof to IP67 and ideal for rough production environments. External devices can be connected using the internal or external I/Os connected via Profibus. The Ethernet interface enables an integration into the standard TCP/IP network.

In addition to these features, the Sedomat 2800+ offers many other advantages for your production.

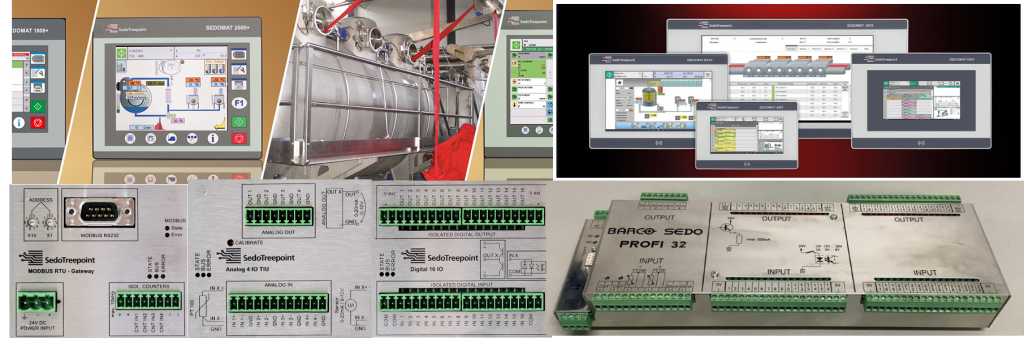

Sedomat 5800+

The Sedomat 5800+ is a good choice for demanding continuous machine automation. The touchscreen operation concept allows even complex processes to be controlled easily. Being water-proof to IP67, it guarantees high quality and reliability for rugged production environments.

Having RFID support, it offers possibilities in data acquisition. External devices can be connected using internal and external I/Os connected via Profibus.

The Sedomat 5800+ offers even more advantages for your production.

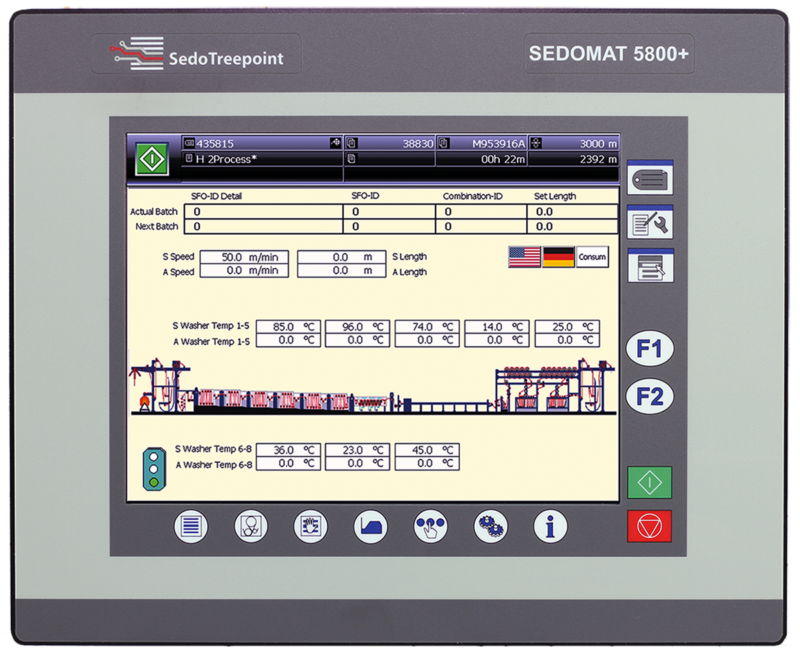

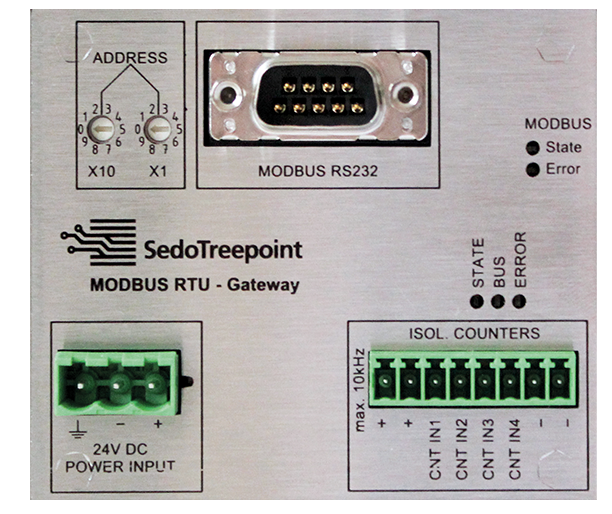

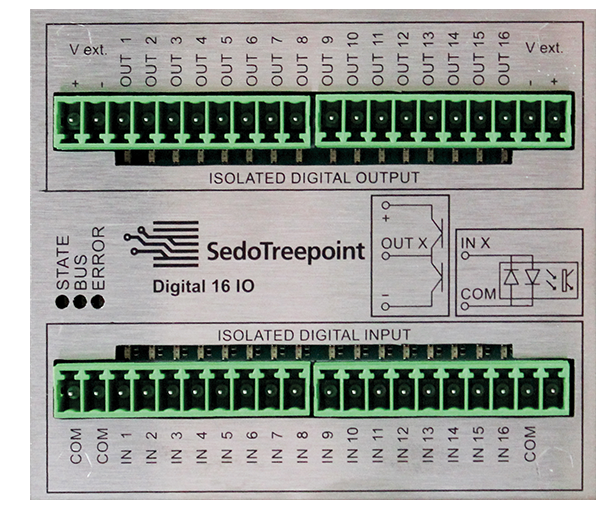

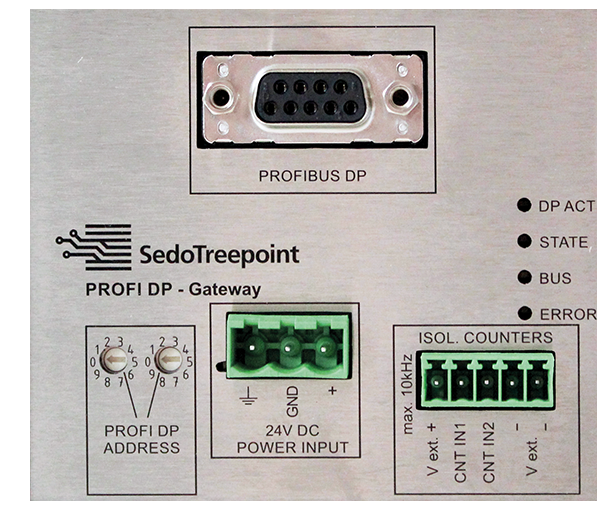

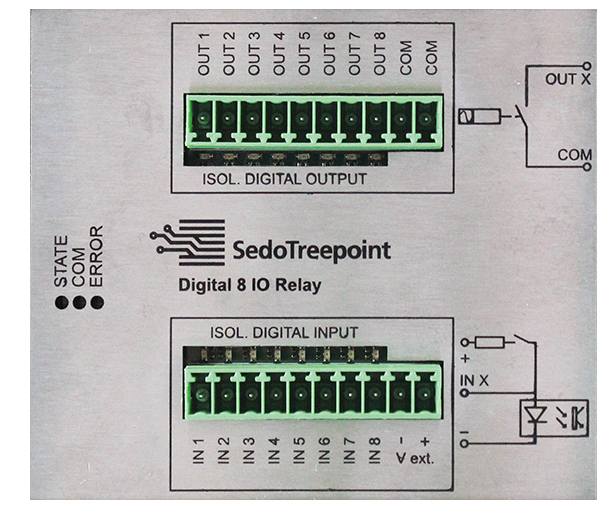

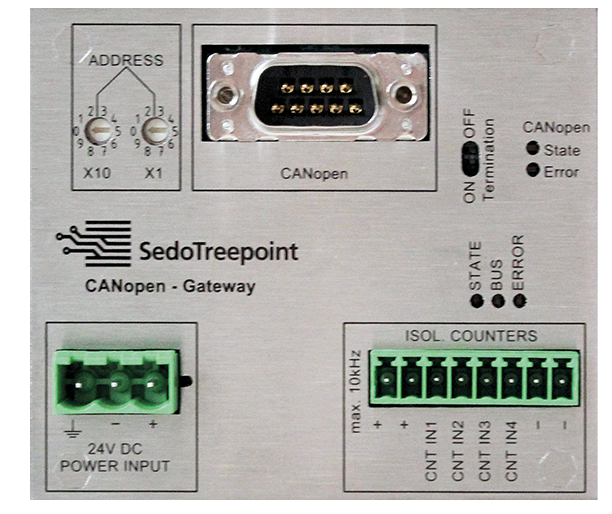

Input/Output Modules

Sedo I/O

Flexible and compact I/O solution

The modular high-performance system is optimized for textile dyeing and finishing machines automation. It can be equipped with CANopen®, PROFIBUS DP® and Modbus RTU interface. One gateway contains up to 6 IO-boards in an aluminum rail housing.

Features

- Up to 6 I/O-boards via PROFIBUS DP® gateway, in an aluminum rail housing

- Switchable digital 16-IO – 24V/GND

- Switchable analogue 4-IO – 0-20mA / 0-10 V / PT100

- Digital 8-IO (relay output)

- Simple address selection via rotary switch

- Compatibility with Profi16/32

- 2 Fast counters (10 Khz)

Concept

- All inputs are equipped with green LEDs and all outputs with red LEDs

- All inputs and outputs are optical isolated

- Status-LEDs showing the actual status

- All connections equipped with plug-in terminals

- Ready to use PROFIBUS DP® cable in desired length on request

- Simple and fast assembly

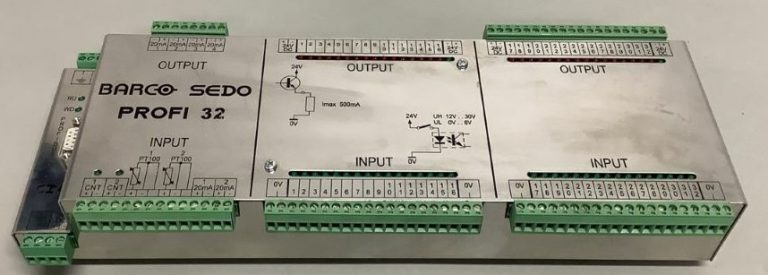

Profi 16 / Profi 32

These units are part of the modular design initiative that enable our Sedomat controllers to operate using either their own I/O, remote I/O or an optimization of the two. These peripheral modules connect to the controllers using a PROFIBUS DP interface and offer both digital and analogue inputs and outputs. Both the Profi 16 and 32 were specialy designed fo the automation of textile finishing machines and are compatible with modules from other suppliers.

Concept:

- All inputs are equipped with green, all outputs with red LED’s.

- All inputs and outputs are optical isolated.

- 4 Status-LED’s showing the actual status.

- All connections equipped with plug-in terminals.

- Ready to use Profibus cable in desired length on request.

Specifications:

Input:

- 2 analogue inputs 0 – 20mA or 4 – 20mA

- 2 PT100 temperature inputs 0-150°C

- 16/32 digital inputs

- 2 counter inputs 800Hz

Output:

- 4 analogue outputs 0 – 20mA or 4- 20mA

- 16/32 digital outputs (max. 0.5A)

Testing & Quality Control

Morapex®

Fast material tests for lab and production

Morapex® is able to analyze and therefore control either raw or dyed material in minutes rather than hours, compared to standard methods. It can be used for textiles (woven, non-woven, knitted, yarn or fibre), paper and leather. The system works according to the method of forced desorption, which means the inner condition of a fabric is revealed.

Morapex® S is a stationary unit developed for a wide range of applications within the laboratory.

Morapex® A is a compact test device for use in production that can operate up to 95°C and the multi-liquor option is able to operate with a wide range of wash liquids

Qtex

Fast and reliable color quality control

Qtex is the ideal tool for colorimetric quality control. The system allows fast, flexible, and competent color evaluation for laboratory and production. Practice-oriented functions support efficient measurement, evaluation, and reporting.

Qtex is a part of the Sedo Treepoint product family and can therefore easily be connected to one or several other systems of the Sedo Treepoint product family. The system can be installed as Client – Server network application